RoboBoat > Mechanical

RoboBoat - Mechanical

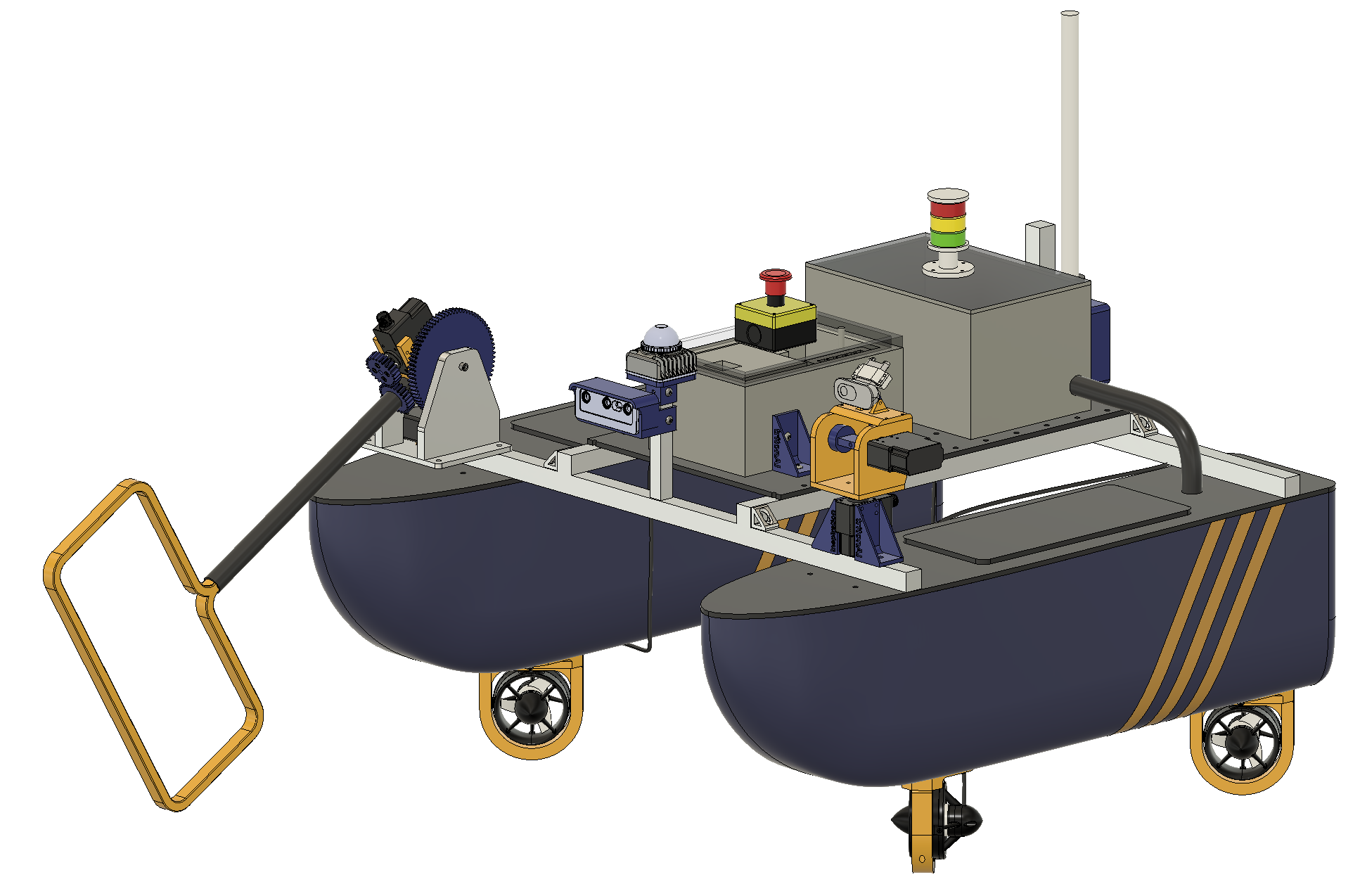

Overview

We elected to use a catamaran over single-hull designs due to higher stability in water combined with lower drag. We based our hull design off Institut Teknologi Sepuluh Nopember’s Nala Proteus while employing our own manufacturing techniques with fiberglass, a durable material used by several teams.

Barco Polo Hull

We wanted to try something new this year and make our hull out of fiberglass. We have made the positive mold, as shown in the video. The positive polystyrene molds were shaped to the contours based on the CAD. We laid a layer of fiberglass sheet and utilized fiberglass mesh to assist with the compressive strength of the boat. We selected curing polyester vinyl from Sunrez for maximum working time and flexibility before dragging the pontoons out into the sun for the final cure. The positive molds were left within the pontoons to impede water pooling in the hulls in the event of a water incursion.

Water Canon

We examined and tested a commercial off-the-shelf water gun to understand its operating mechanism and limitations. The water gun relied on gravity and a motor to flush water out, but unfortunately failed to produce the steady stream required by the RoboBoat rules.

As such, we are designing a water squirter with a pump to suck water from the competition venue and two motors on the pitch and yaw axes. Separate movement of the water cannon relative to the boat saves time that would be used rotating the boat and returning it to a standstill.

Additionally, this capability allows us to complete the Duck Wash task quicker as Barco Polo can leave the Docking task without having to park in front of the yellow duck banner.

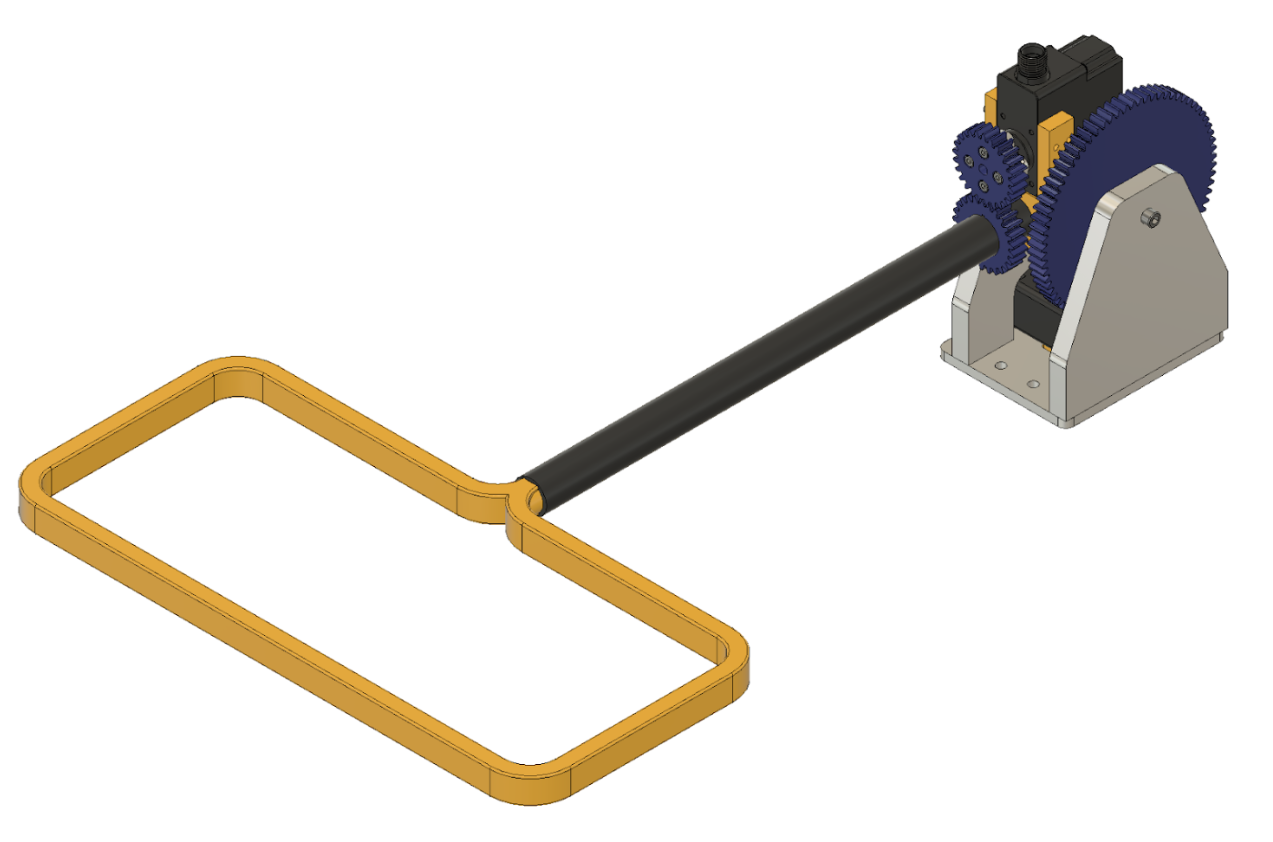

Arm

Given our short timeframe for design and production, as well as our team’s emphasis on boat vision and navigation, it was imperative to make design choices that limited mechanical complexity. After careful consideration, we decided to use a tilted net attached to an elevator system to indiscriminately pick up task objects, which would then be delivered to any collection site (as teams are not penalized for depositing into incorrect sites). We determined that nets would significantly reduce boat drag and tilt while the collection task is being attempted. Another elevator-like system will provide linear extension and stowing capabilities, as well as giving us more effective reach and greater collection opportunities. In prioritizing vision, our plan is for our boat to detect the collection octagon via the marker cube, extend the net over the first octagon, sink the net via the elevator system and then traverse the perimeter of the outer octagon. Both components of the arm will use a gear and belt system to transfer torque from the motors into linear motion.

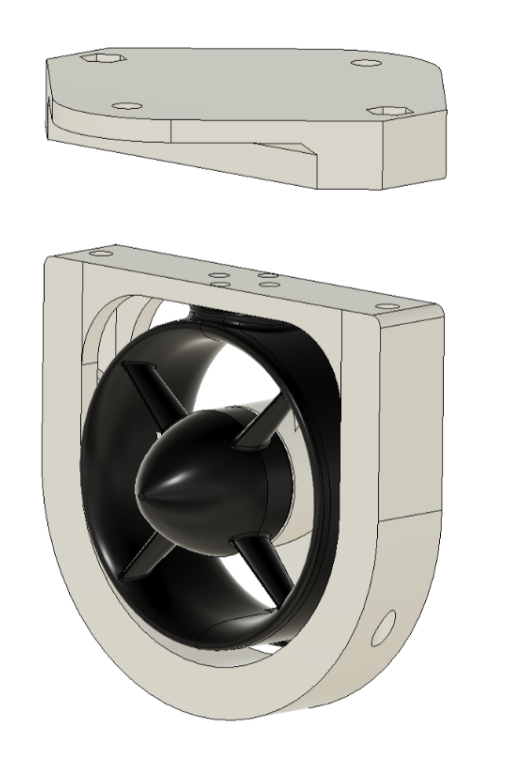

Thruster Gaurds

From our previous experiences in RoboSub and RobotX, our team has realized the importance of strong thruster mounts and shrouds. These new thruster guard enables positioning of thrusters and provides a failure point during harsh impact which will fail before the injection molded case of the t200 thrusters fail.