RoboBoat 2026 > Mechanical

RoboBoat - Mechanical

Overview

We elected to use a catamaran over single-hull designs due to higher stability in water combined with lower drag. We based our hull design off Institut Teknologi Sepuluh Nopember’s Nala Proteus while employing our own manufacturing techniques with fiberglass, a durable material used by several teams.

Crusader Hull

We exported a scale model of the boat and cut out wood and foam pieces. After that, we sanded down the hulls with the orbital sander to make them smoother. Any gaps were filled in with total-fair. After that, we cut fiberglass to the boat's size while ensuring the edges are feathered. We contributed to the addition of two more layers of fiberglass, allowing it to cure faster under UV light. Any excess fiberglass was cut off after curing. Next, a layer of total fiber was added to smooth out the fiberglass on both hulls. A CAD model was created in the meantime to determine the thruster mounting locations and the location of the electrical box. Finishing the hulls with blue paint, we allowed them to dry and in the meantime, we attached the thrusters, 80/20 aluminum extrusions, and the electrical box.

Water Pump

Networking with other RoboBoat teams, we decided on procuring an off the shelf water pump from Amazon. Coupled with a nozzle to accelerate the water we are able to perform the Water Delivery task 2 feet away from the Orange Vessels. The pump extracts water from the lake at the competition venue.

Racquetball Launcher

Leveraging past experience from land vehicle competitions the team decided to implement a puncher mechanism. A DC motor powers the driving gear, which contains only 3 teeth. The gear compresses the spring by drawing back the rack on the punching rod, as the drive gear continues the rotation, the rack slips and the punching rod launches the racquet ball towards the Black Vessels.

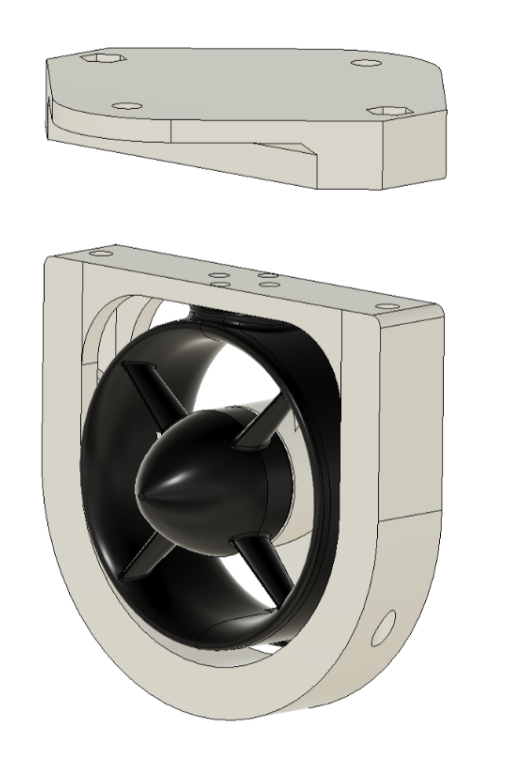

Thruster Guards

From our previous experiences in RoboSub and RobotX, our team has realized the importance of strong thruster mounts and shrouds. These new thruster guard enables positioning of thrusters and provides a failure point during harsh impact which will fail before the injection molded case of the T200 thrusters fail.