New Boat Fabrication Process

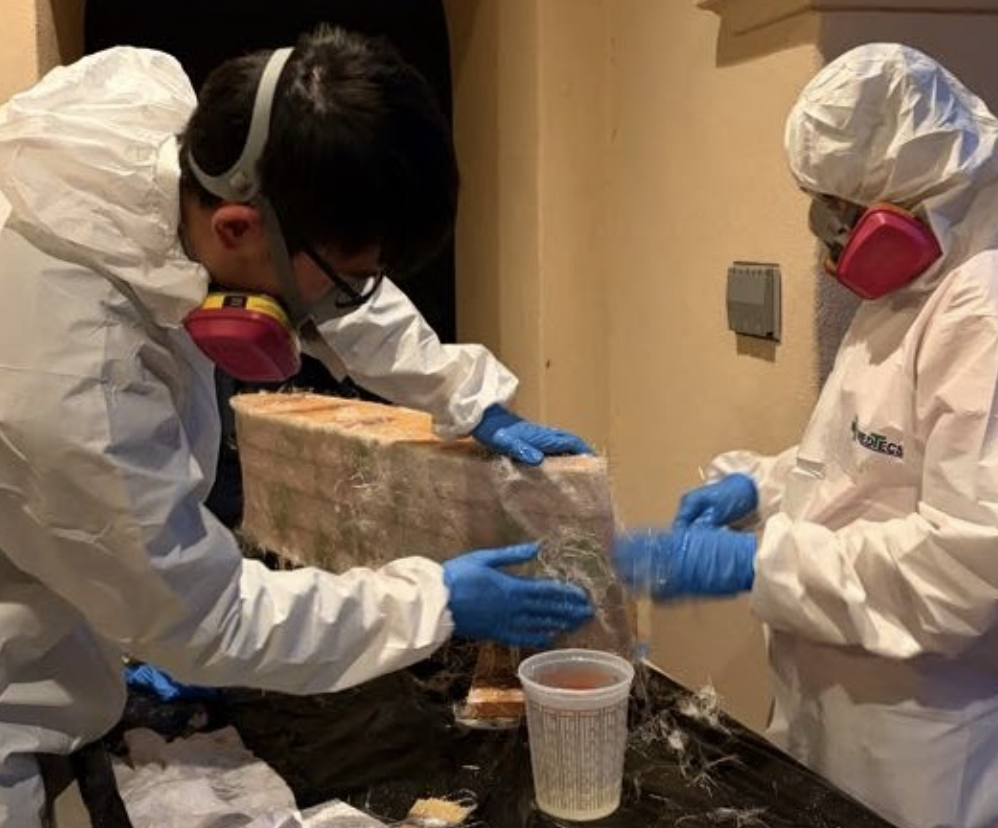

First practice (11/16/2025)

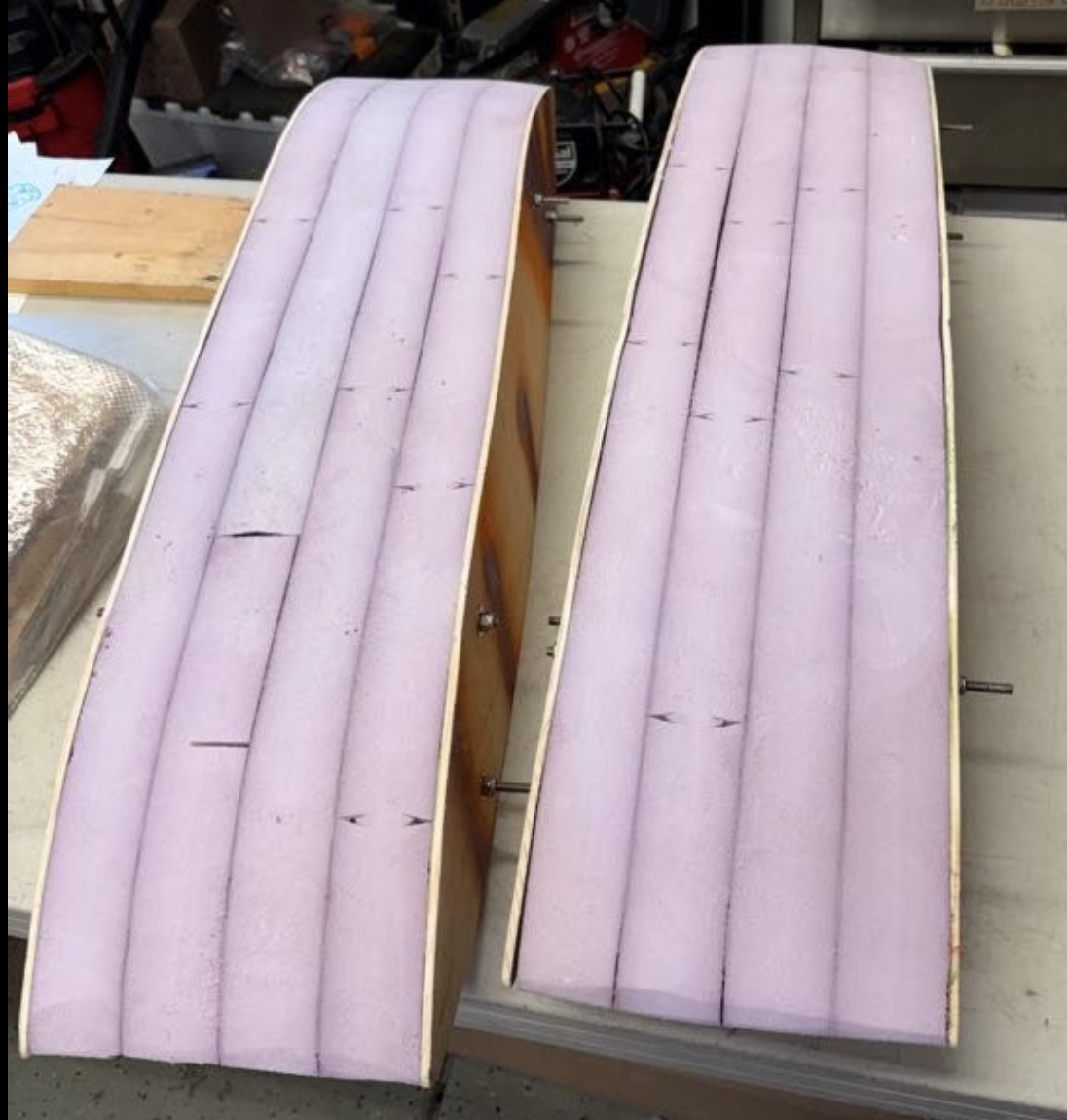

After that, we used wooden boards and foam from prior competitions and cut them into our desired shape. Because some sides were uneven, we sanded it smoothly with an orbital sander until all of the pieces shared the same dimensions. Using Super 77, we attached the pieces of wood and foam together, creating two hulls.

Sanding the foam (11/24/2025)

Applying epoxy resin (11/25/2025)

After the hulls had been manufactured, we were able to assemble the boat’s structure, leading to the following result (11/25/2025)

Utilizing uv cure resin allowed the team to take their time (3 hour layup time process) and fix their mistakes (11/25/2025)

This year, in order to score inter-vehicle communication points for the new Roboboat tasks, we created a new boat, using a design similar to Barco Polo’s, but with a few changes.

In order to let new team members gain experience, we first built two small scale hulls for practice.

Second practice (11/22/2025)

Finished sanded foam (11/24/2025)

Then, we added a coat of Total Fair for some uneven surfaces. We applied fiberglass, which was crucial for waterproofing, and applied several coats of epoxy resin for sticking the fiberglass on the hulls.

Once the epoxy resin dried, we added another coat of Total Fair and waited for it to dry. For a smooth surface, we used the orbital sander to sand the uneven surfaces. As a finishing touch, we added two light coats of blue paint for each hull.

Applying final coat of total fair for smooth surface (11/26/2025)

Final boat (12/01/2025)

Here is an updated version of the boat’s progress + steps we took: